Wear measurement

Wear

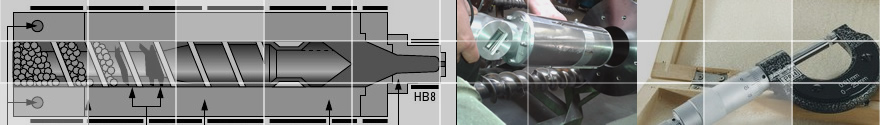

During extrusion or injection moulding the plastics moulding material is transported in the cylinder through the rotation of the screw and plasticised. This holistic process inevitably causes wear

Significant influencing variables on the wear are:

- plastics

- processing parameters

- design of plasticizing unit

- material combination of the screw, the cylinder and the non-return valve

Types of wear

We distinguish various types of wear, such as:

- abrasion (micro-cutting)

- adhesion (cold welding, seizing)

- surface cracking (fatigue wear)

- tribochemcial reactions (layer wear)

Wear measurement

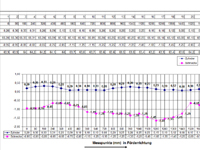

By means of measuring devices especially developed by us we carry out wear measurement at your site and we may let you know immediately the rate of wear as well as our resulting recommendation.

Our recommendation is based on our 40 years' experience and on the holistic process view. In this way we can, for example, besides the usual regenerating give recommendations as to a new screw geometry which reduces wear.

The perfect combination

With the combination of wear measurement and process optimisation screws can be produced which are tailor-made to your particular application. This ensures a higher process security and minimises the machine downtime.