Screws

Development

The technical progress in the plastics processing constantly creates new requirements. In order to be able to offer the newest solutions, consequent further development of products is essential.

Manufacture - Screws à la carte

Know-how, modern production methods and customer-oriented thinking determine the high quality of Arenz screws.

Due to our more than 40 years of experience we can offer you a wide range of products. Thus we guarantee customised screw geometries.

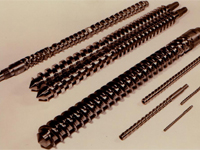

Arenz screws

We produce performance-optimized, highly wear- and corrosion resistant screws that are tailor-made according to customer requirements.

- three-zone screws

- barrier screws

- vented extruder screws

- twin screws

- conical or parallel

- rotating or counter-rotating

- multi-part screws

Including all screw components as e.g.:

- mixing parts, shearing parts, spiral shearing parts

- screw tips

- diameter:

up to 500 mm

- length:

up to 7,000 mm

- Hard-facing

By means of our plasma powder welding machine we are able to process any standard hard-facing material using the PTA welding procedure.

In particular, Arenz has developed its own hard-facing materials (see hard-facing materials).

For certain applications the geometry must be protected by a caoting.

We offer the following treatment methods:

- hard chrome plating

- chemical nickel plating

- TiN coating

- CrN

- CrN-mod

- CrN-multilayer coating

- high-speed flame spraying

- nitrided steel

- powder metallurgical steel

- nickel-based materials for extremely high corrosion and temperature resistance (e.g. Inconel, Hastelloy)

| Item | Alloy | Hardness |

|---|---|---|

| Arnit 100 | cobalt-base | 50 - 60 HRC | Arnit 110 | cobalt-base | 38 - 45 HRC | Arnit 120 | cobalt-base | 41 - 48 HRC | Arnit 200 | Nickel-Basis | 51 - 54 HRC | Arnit 210 | nickel-base | 52 - 57 HRC | Arnit 300 | Iron-base | 56 - 62 HRC |